Polypropylene dyeing drums

They are produced with high polypropylene plates, resistance to

chemicals, temperature and abrasiveness. These equipment’s are traction

for entire crown in ring “reamed” providing high strength, durability and

smooth movement.

The polypropylene dyeing Drums allow for greater flexibility of production and

can use the same equipment for different processes. Is easy to wash,

because it does not absorb the color has surface extremely smooth, what

ensures better finishing in leather.

√ Manual or automatic sliding doors in stainless steel AISI 316 l.

√ Hardware’s in stainless steel or in steel with special PVC protection.

√ Internal system palettes and billets in polypropylene.

√ Polypropylene drainage system.

√ Full Drive as need and client usage.

√ Chutes made of fiberglass, polypropylene or stainless steel, with output

directed to the facilities project.

• Full electrical panel as standard NR10

• Manual drain valves (drawer model) or pneumatic

• Recirculation System, type “laboratory” produced in STAINLESS STEEL AISI 316l

or in polypropylene (for the control and administration of the baths, without

need to stop the equipment for analysis and technical corrections during the

process. This system is connected to the drum through piping 316L stainless steel

with an intermediate valve to interrupt the process)

• Stainless steel Solid separator Filter M1 (automatic cleaning system of fluids

with solid residues)

• Meter and temperature controller by steam injection valve on/off control

• Protections and safety devices according to the project

Brazil is one of the main leather producers in the world and Michelon Máquinas has participated in this development and construction over time, through the manufacture of high-quality tannery drums and skilled technical assistance.

Through an extraordinary combination of factors, Brazil has become one of the largest cattle producers in the world, it is also one of the largest shoe producers on the planet. Thus, there is an availability of bovine hides, around 40 million per year, and an advanced capacity and technology in the footwear sector, at the peak of consumption.

These two sectors are interconnected by another sector that stands out worldwide: the Brazilian tanning industry, which supplies the domestic and foreign markets with quality, serving the most demanding markets in the world. Tannery Drums or Tanning Drums have a great deal of collaboration in this supply capacity.

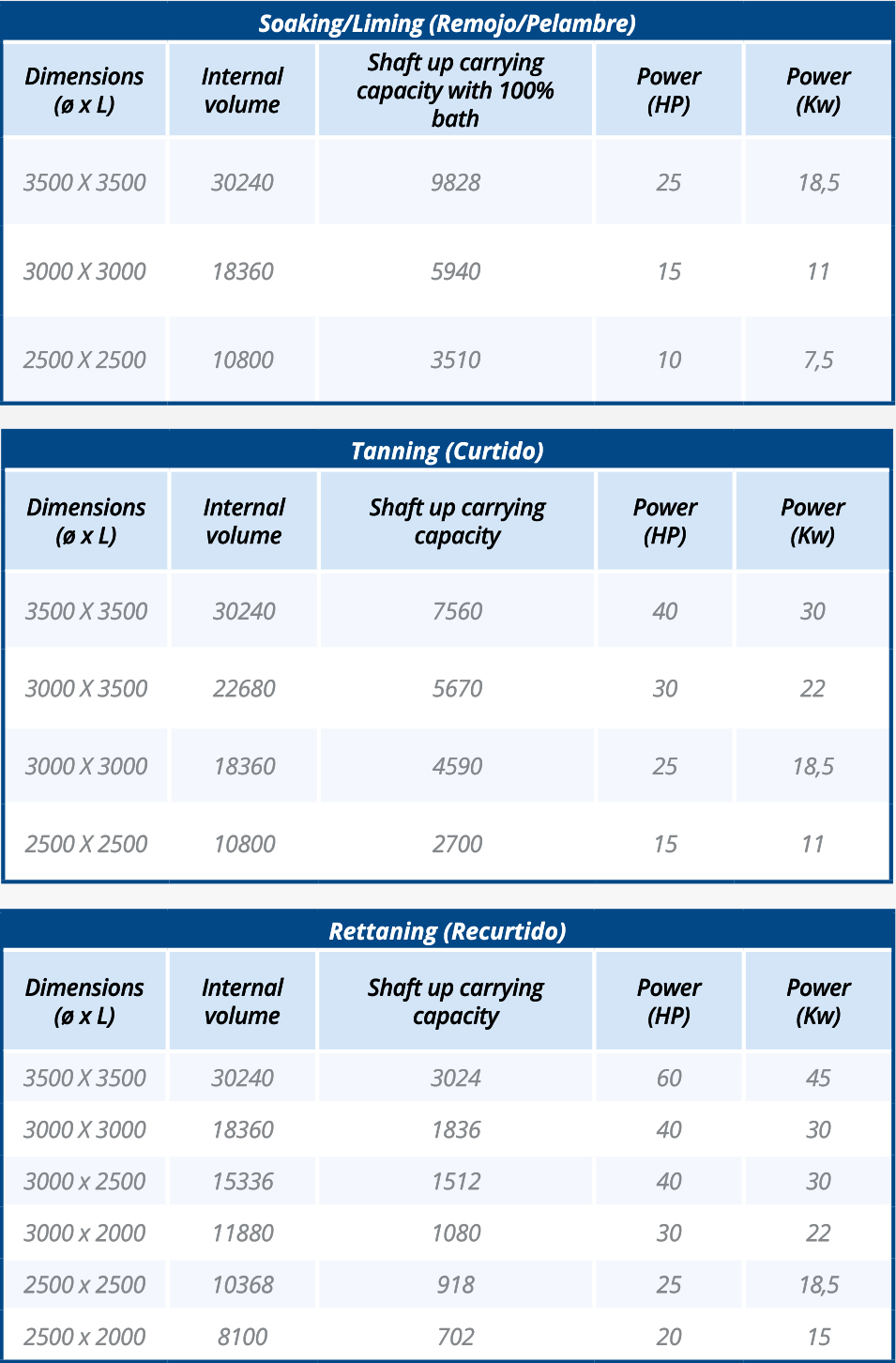

Along with the leather industry, Brazil developed its industry of machinery for the manufacture of leather, which today is a reference in providing technological solutions for this sector. In this scenario, Michelon has an important highlight, as it is a leader in the manufacture of tanning drums, one of the main pieces of equipment that make up the tanning production process. Soils are responsible for the Liming, Tanning and Retanning processes. Knowing the importance of this equipment, we use quality raw materials in our wooden drums and we were pioneers in Brazil in the manufacture of polypropylene drums, a renowned solution that allows us to use the same equipment for different processes.