Multiaction Tanning Drum's

Michelon, traditionally known by its constant search for technological innovation, not only looking for optimization but for costs reduction on the productive process as well, offers a product with its own technology named Multiaction Drum.

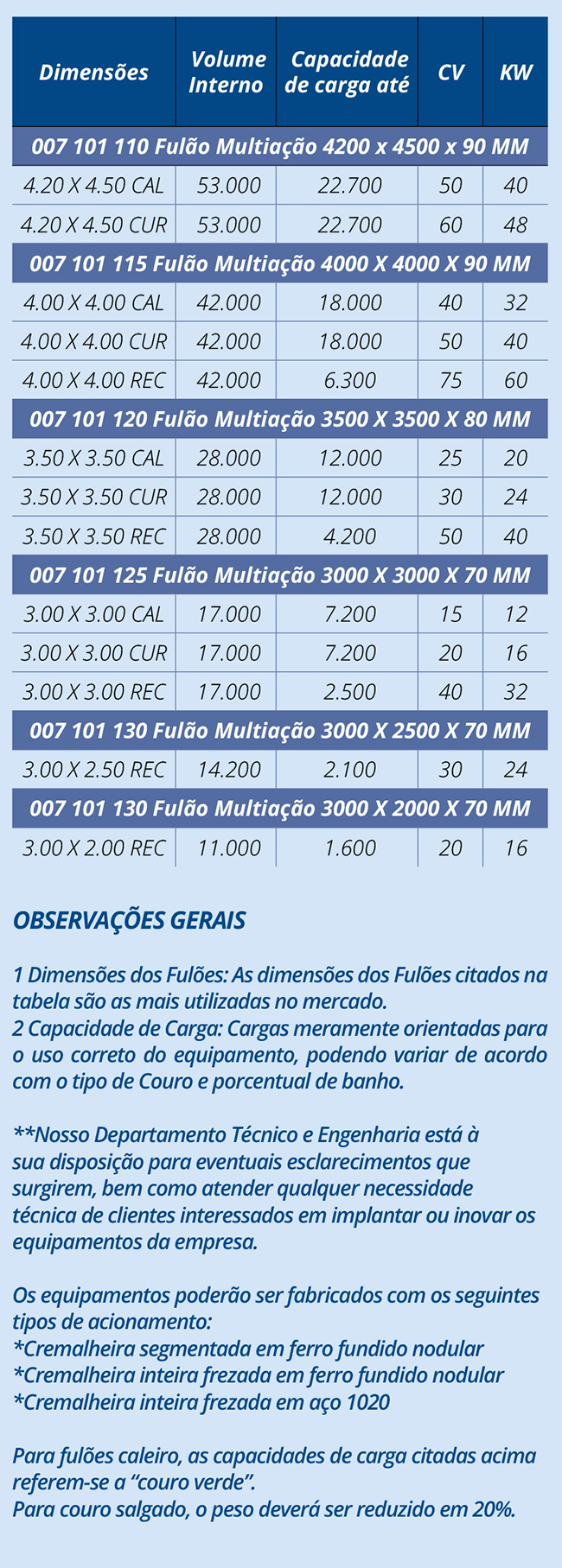

Capable of being used for Liming, Tanning and Retanning, Multiaction Drum is a tool that presents as main

characteristic the load increase, and with the reduction of the bath percentage compared to the conventional equipment is able of providing high productivity allied to the best leather quality. Besides, the Multiaction Drum keeps the mechanic effect on the hides in both spin tracks, making the load and unload processes easier. It also allows a flexible production in the process of small, medium and large loads, depending on the company’s productive necessity and capacity.

ADVANTAGES OF THE MULTIACTION DRUMS

• Best quality of the processed hides

• Reduction of the energy and water consume

• Reduction of the effluent treatment consume

• Possibility of producing with the same equipment,

small, medium and large loads

• Better distribution of the activation efforts (left

and right spins)

REDUCTION OF THE COMPANY’S COSTS

Productivity increase with the same equipment,physical area and collaborators. On an average basis we could confirm:

Liming................30 a 50%

Tanning..............60 a 80%

Retanning...........60 a 100%

REDUCTION OF THE ENERGY CONSUME

The equipment will remain with the same engine power or in some cases, the power will be reduced, making

possible the energy’s consume decrease for the produced leather. Overall, it is likely to assure that the consume

reduction is about 50% achievable.

REDUCTION OF THE WATER CONSUME

Due to the load increase that varies from 30 to 100%, the quantity of utilized water will be proportionally reduced. Therefore, depending on the bath percentage for each process, the reduction might reach 50%.

Brazil is one of the main leather producers in the world and Michelon Máquinas has participated in this development and construction over time, through the manufacture of high-quality tannery drums and skilled technical assistance.

Through an extraordinary combination of factors, Brazil has become one of the largest cattle producers in the world, it is also one of the largest shoe producers on the planet. Thus, there is an availability of bovine hides, around 40 million per year, and an advanced capacity and technology in the footwear sector, at the peak of consumption.

These two sectors are interconnected by another sector that stands out worldwide: the Brazilian tanning industry, which supplies the domestic and foreign markets with quality, serving the most demanding markets in the world. Tannery Drums or Tanning Drums have a great deal of collaboration in this supply capacity.

Along with the leather industry, Brazil developed its industry of machinery for the manufacture of leather, which today is a reference in providing technological solutions for this sector. In this scenario, Michelon has an important highlight, as it is a leader in the manufacture of tanning drums, one of the main pieces of equipment that make up the tanning production process. Soils are responsible for the Liming, Tanning and Retanning processes. Knowing the importance of this equipment, we use quality raw materials in our wooden drums and we were pioneers in Brazil in the manufacture of polypropylene drums, a renowned solution that allows us to use the same equipment for different processes.